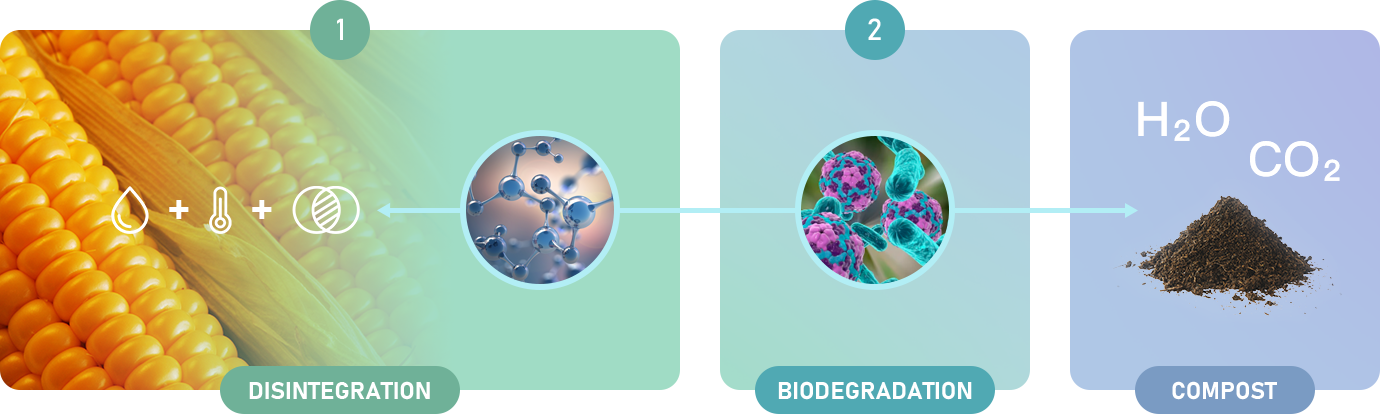

The main raw material of polylactic acid resin SUPER PELLET comes from natural materials such as corn, which is environmentally friendly and the production process is pollution-free. Moreover, the product can be biodegradable into CO2 and water within 3-12 months, making it an ideal green material New polymer materials. PLA has excellent plasticity, biocompatibility, and outstanding processing and physical properties, It is currently the main bio based plastic that can compete with traditional petroleum based plastics.

sucrose

Derived from plants

Natural safety

Biodegradation

lactic acid

Polylactic acid resin PLA

Product Forming

sunlight

+

temperature

+

humidity

SUPER PELLET

Source nature return nature

Glucose is extracted from plant starch and then fermented to obtain food-grade lactic acid, which is polymerized into polylactic acid resin with different application properties. The SUPER PELLET is composted and fully degrades into carbon dioxide and water.

Extracting glucose from plant starch and fermenting it to obtain food grade lactic acid, which is then polymerized into polylactic acid resins with different application properties. SUPER PELLET can be completely degraded into carbon dioxide and water through composting.

Advantages of polylactic acid

-

Advantages of raw materials

Raw materials come from food grade lactic acid such as Corn starch

Unhook plastic from fossil materials

Can create a weak acidic environment on the surface of the product, with antibacterial and anti mold effects

-

environmentally friendly

low carbon dioxide

Global Biology Decrease, Natural Return, Reduction of White Pollution

-

Disposal and recycling advantages

Incinerable, clean burning, with a carbon dioxide emission of one-third that of traditional plastics

Compostable, completely degraded into carbon dioxide and water

Landable, without leachate or methane release

Recyclable, physical/chemical recovery compliant

The principles of circular economy and sustainable material management

CN

CN